广西梧州制药厂废水处理站污水处理设备

济宁天通水处理设备有限公司的产品以废水处理站、废水处理工艺、废水处理设备、工业废水处理设备、水处理设备、生活废水处理设备、环境废水处理设备等设备为主。济宁天通水处理设备有限公司位于山东省济宁市任城区交通方便,地理。公司的售后服务人员业务熟练、技术,承诺对产品实行终生服务,急用户所急,想用户所想,大限度的满足用户的要求。始终坚持“质量,用户至上”的方针,受到用户的广泛好评。的产品,周到的服务是我公司始终如一的宗旨!济宁天通水设备设备有限公司愿与社会各界朋友携手共进,共同发展!

一废水来源及水质

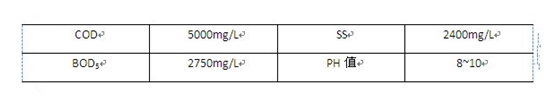

广西梧州某制药厂的废水主要是生产青霉素所产生的高浓度有机废水,水质情况见表

该类废水的主要特点是有机物浓度高,成分复杂含有石油类、胺类、酸类、破乳剂等污染物。除此之外水中含有难以解释的大分子苯环物质和浓度很高的SO2﹣4及其盐类,这些物质将严重抑制微生物对水中有机物的生物降解。因此,正确选用合适该类废水处理工艺是处理成功与否的关键。

二 处理工艺流程及说明

1 调节池

调节池主要用于调节来水的水量和水质的不均匀性。调节时间按8h设计

2 反应池

反应池采用6格穿孔旋流反应形式,孔口流速由1.0m/s逐格递减至0.15m/s。反应时间20min左右。

3 沉淀池

采用斜板沉淀池。斜板间距80mm,表面水力负荷2.1m³/(㎡•h).

4水电解酸化池

水解酸化工艺主要用来使难易降解的苯环物质、大分子有机物开环断链,变为易于生物降解的小分子物质,对改善废水的可生化性,有利于后续好氧生物降解。

本工程设计水解酸化时间为15h,池内设置弹性填料和水下曝气装置。

5 生物选择器

在SBR反应池进水端部设置生物选择器(又称与反应区),使回流的活性污泥和原水中的有机物在此处达到充分混合和吸附,使回流的大量微生物得以淘劣选优、培养和驯化,诱导出活性很强的微生物群体,并能抑制丝状菌的生长和繁殖,对后续好氧反应控制污泥膨胀具有重要作用。改反应过程一般45min~60min即可完成。

6 SBR工艺又称序批式间歇活性污泥法,是近几年国内兴起的集生物降解、沉淀、排水、排泥等功能于一体的污水生化处理工艺。在运行过程中,采用PLC可编程序控制器,按时间和液位实现全过程自动控制。

本工程设置3座SBR反应池,每池运行周期12h。其中充水期4h,反应期8h(其中包括充水期3.5h),沉淀期1.5h,排水期1.5h,闲置期0.5h,MLSS为3500mg/L.

7 污泥处理系统

本工程污泥分为化学污泥和剩余活性污泥两部分。前者经初沉淀池排出,直接进入污泥脱水系统;后者在每座SBR池里内置1个8m×5m×8m的浓缩池,浓缩后的污泥经提升泵回流至生物选择器和水解酸化池,剩余污泥与化学污泥一起储存于污泥池内,进行脱水外运。污泥脱水设置5台带式压榨过滤机,带宽2m.

三工程运行效果

通过三个多月的效果和监测,处理效果显著,运转稳定。其中在混合沉淀工艺中实际COD去除率为40%~50%,BOD5去除率为30%~50%。SS去除率为60%~70%;在水解酸化工艺中,COD去除率为25%~35%,BOD5去除率为20%~25%.

厂家联系电话:

联系人:范经理

The products of Jining Tian Tong water treatment equipment Co., Ltd. are mainly composed of wastewater treatment station, waste water treatment process, waste water treatment equipment, industrial wastewater treatment equipment, water treatment equipment, domestic wastewater treatment equipment, environmental wastewater treatment equipment and other equipment. Jining water treatment equipment Co. Ltd is located in Shandong City, Jining Province, the city traffic is convenient, the geographical advantages. The after-sales service personnel of the company are skilled in business and skilled in technology. They promise to carry out lifelong service for products. They are anxious for users to satisfy users' requirements to the maximum extent. Always adhere to the "quality first, the customer first" policy, received by the user's extensive praise. The first class product and the considerate service are the consistent tenet of our company. Jining Tian Tong Shui Equipment Co., Ltd. is willing to work together with friends from all walks of life to develop together.

A waste water source and water quality

The wastewater from a pharmaceutical factory is mainly a high concentration organic wastewater produced by the production of penicillin. The water quality is shown in the table.

The main characteristic of this kind of wastewater is the high concentration of organic matter, and the composition is complex containing petroleum, amines, acids, demulsifier and so on. In addition to very high SO 2 - 4 and its salts of macromolecular substances and the concentration of benzene in water containing hard to explain, these substances will seriously inhibit the biodegradation of organic compounds in water. Therefore, the key to the success of treatment is to choose the proper treatment process of this kind of wastewater.

Two process process and description

1 regulating pool

The regulating pool is mainly used to adjust the inhomogeneity of water and water quality. The adjustment time is designed according to 8h

2 reaction pool

In the reaction pool, the 6 lattice perforation swirl reaction was used, and the pore flow velocity decreased from 1.0m/s to 0.15m/s. The reaction time is about 20min.

3 sedimentation tank

The inclined plate sedimentation tank is used. Inclined plate spacing 80mm, surface load 2.1m / (M - fand h).

4 water electrolysis acidification pool

Hydrolytic acidification technology is mainly used to make the difficult degradation of benzene ring substances and macromolecular organic compounds open and chain broken, and become biodegradable small molecules. It can improve the biodegradability of wastewater, and is conducive to subsequent aerobic biodegradation.

The time of hydrolysis and acidification of the project is 15h, and the elastic packing and underwater aeration device are set up in the pool.

5 biological selector

In the SBR reactor inlet is arranged on the end of the bio selector (also called with the reaction zone), the organic reflux and activated sludge in the raw water to fully mix and adsorption here to Amoy bad selection, cultivation and domestication of large numbers of microbial reflux, micro biological groups induce high activity, growth and reproduction and can inhibit the filamentous bacteria, the subsequent aerobic sludge reaction control plays an important role in the expansion. The reaction process can be completed by 45min~60min.

6 SBR process, also known as sequencing batch activated sludge process, is a biological wastewater treatment technology developed in recent years, which integrates functions of biodegradation, sedimentation, drainage and sludge discharge. In the process of operation, the PLC programmable controller is used to realize the automatic control of the whole process according to the time and level.

3 SBR reaction pools are set up in this project, and the operation cycle of each pool is 12h. The water filling period is 4h, the reaction period 8h (including the water filling period 3.5H), the precipitation period 1.5h, the drainage period 1.5h, the idle period 0.5h, MLSS as 3500mg/L.

7 sludge treatment system

The sewage sludge is divided into two parts, chemical sludge and residual activated sludge. The former after the primary sedimentation tank discharged directly into the sludge dewatering system; the latter built in a concentrated pool SBR pool of 1 8m * 5m * 8m, after the sludge concentration by the lift pump back to the biological selector and the hydrolytic acidification tank, sludge and chemical sludge with sludge stored in the tank, dewatering sinotrans. 5 belt press filters are set up for sludge dewatering, and the bandwidth is 2m.

Operation effect of three project

Through more than three months of effect and monitoring, the treatment effect is remarkable and the operation is stable. In the mixed precipitation process, the actual removal rate of COD is 40%~50%, and the removal rate of BOD5 is 30%~50%. The removal rate of SS is 60%~70%, and in the hydrolysis acidification process, the removal rate of COD is 25%~35%, and the removal rate of BOD5 is 20%~25%.

Manufacturer contact phone:

Contact: Manager fan